There is a plethora of commercial and industrial machines, products and components that depend on metal fabrication. From toaster enclosures and blender bases to the steel skeleton of buildings, this industry is responsible for many metal products you use every day.

Metal Fabrication Boise Idaho includes cutting techniques, forming techniques like folding and stretching, and welding methods that join together metal pieces. This article will cover the most popular types of metal fabrication methods, including cutting, punching, shearing, forging, stamping and welding.

Cutting

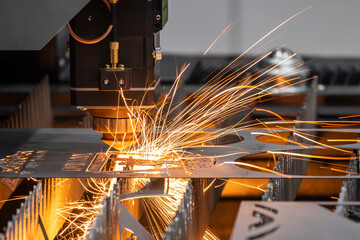

Cutting is one of the most common types of metal fabrication techniques. It involves dividing a larger piece of metal into smaller parts and is performed with a range of tools and equipment. Some popular cutting metal fabrication processes include laser cutting, fibre laser cutting, oxy-fuel cutting, and plasma cutting. These methods are highly efficient, accurate and require little human intervention.

Machining is another popular type of cutting, which uses a machine like a lathe to remove pieces of the metal. This process is especially useful when the final product requires precise dimensions and a clean finish. Other types of cutting include punching, blanking, shearing, and bending. These are often used for creating holes in a sheet of metal or for fastening latches.

Bending is a more complex form of reshaping metal into new shapes. It can be done through cold, warm or hot forging. Cold forging uses a press to force the metal into a shape. Warm and hot forging involve heating the metal to make it pliable and then using a die or hammer to shape the metal.

Some metal components need to be bent into a specific angle. This is a common process in forming, which can be done by hand or with high-tech equipment. Other forms of bending include abrasion, spinning, and stamping. These are often used in artisan crafts, such as jewellery or medieval armour.

Punching

When a hole needs to be created in a metal sheet, punching is often the quickest and least expensive option. Manufacturers use this technique to create a series of holes in a sheet of metal in medium-to high production volumes. In some applications, metal punching can be done while the material is still hot. This method is known as blanking or hot punching.

Another common fabrication process is shearing. This involves cutting a piece of metal into smaller sections through a machine. Manufacturers can also shear metal by hand if the final product doesn’t require precise dimensions.

Folding is a more complex fabrication process. It involves manipulating a metal surface to bend it at specific angles. This is generally performed in facilities that specialize in this type of metalworking because it requires specialized equipment.

Metal fabrication is a critical part of the manufacturing industry. It is used to produce a variety of products and components, from heavy machinery and transportation infrastructure to metal art and public installations. For example, you’ll find the results of metal fabrication in conveyor systems for industrial factories and railways, as well as standard and specialized ductwork throughout homes and commercial buildings. Metal fabrication is even used to craft signage and support structures for bridges, as well as aesthetically pleasing sculptures in public spaces. This is all made possible by the various fabrication processes like cutting, punching, casting, machining, and forging.

Shearing

Shearing is a common metal fabrication technique used to trim and remove excess material from sheet or plate metal. This process uses a machine or tool to slice through the metal with extreme precision. Shearing doesn’t use any heat and produces little waste in the form of chips, making it an effective and efficient way to cut metals.

Other shearing techniques include guillotine shearing, which involves using a machinist-made machine to cut through metal sheets or plates with a straight blade. Guillotine shears can be powered mechanically, hydraulically or manually. Rotary shearing, on the other hand, uses rotating blades to cut through metals. This method is ideal for cutting thicker materials and creating patterns.

Both shearing and sawing are two of the most common types of metal fabrication processes that deliver consistent, accurate cuts across a wide range of industries. However, the quality of a cut can depend on several factors, including the type of metal, design complexity and fabrication techniques.

From repairing vehicles to manufacturing specialized components for spacecraft, metal fabrication is crucial for many different sectors. In the automotive industry, it’s used for producing body panels and frames while also delivering high-performance engines. In the energy sector, it’s important for constructing pipes and tanks. It’s also utilized in the military, where strength and durability are key requirements, as well as in the medical field for crafting a wide range of surgical instruments.

Forging

Forging is a metal fabrication process that uses intense heat and high pressure to shape raw metal into its desired form. The technique manipulates the metal’s internal structure and microstructure by compressing it under immense force, which can create components with greater dimensional accuracy and superior mechanical properties than those produced through casting or machining from bar stock.

Forged parts are typically stronger and more durable than those made by other methods, making them ideal for critical applications that require reliability and safety. This makes them popular in industries such as aerospace, automotive and oil and gas for manufacturing components like gears, crankshafts and valves/pipelines. The process also helps produce larger components with complex shapes and tighter tolerances than would be possible with casting or machining from bar stock.

While a variety of forging techniques exist (cold, warm and hot forging), all share common features. They include a stressing operation that manipulates the material’s shape according to engineering drawings and 3D models, as well as careful die design to minimize material waste.

The forging process also involves metallurgical refining through tempering, solutioning and annealing. Tempering involves heating the material above its recrystallization temperature, holding it at this elevated temperature for a length of time and then cooling it rapidly to harden it without cracking or deforming it. Solutioning is a more complicated technological process that combines hardening with tempering and is useful for stainless and acid-resistant steels. Finally, annealing is an important metallurgical process that reduces brittleness and improves workability.

Stamping

The stamping metal fabrication process uses custom-designed dies to shape flat sheet metal into specific shapes. It’s a popular process that manufacturers use for high-volume production jobs and complex components. In addition to stamping, it includes other sheet-metal forming manufacturing processes such as blanking, punching, and bending.

Another specialized form of metal fabrication, drawing involves pulling or stretching the metal to make it thinner than normal. It can be done at room temperature or with the aid of heat, depending on the material and the desired outcome. For instance, drawing makes it easier to transform a flat metal piece into a vessel with a cylindrical or box-like shape.

While welding and metal fabrication are different, they’re both crucial parts of the manufacturing process. While welding is the joining of pieces using fusion, metal fabrication is a more broad process that can include other specialized techniques like forming, bending, and spinning. It also involves more centralized steps like design and cutting. Metal fabrication requires a more comprehensive set of tools and skills than welding, but both are critical to creating durable and quality products for consumers.

Welding

Welding is the final step in metal fabrication, joining different pieces of metal to create a finished product. This process uses heat to liquefy both the parent and filler metals, creating a strong bond that can hold up against significant strain. There are several different types of welding metal fabrication processes, including MIG and TIG welding, robotic welding, and arc welding.

Arc welding is a common metal fabrication technique that uses an electrical arc to melt and join together two pieces of metal. It can be used on a variety of metals, and it produces a stronger weld than other types of welding.

Shearing is another popular metal fabrication technique. It involves cutting a sheet of metal into the desired shape using a blade that’s either above or below it. The upper blade pushes down on the lower one, causing the metal to be sliced into smaller pieces. Shearing is ideal for achieving straight and long cuts, but it can also be used to cut materials with different shapes.

Machining is a type of metal fabrication that uses machines to clip off specific parts of a piece of metal. This method is commonly used for creating prototypes and high-volume production, and it’s especially effective for working with thinner materials. This is because it can be done quickly and easily, requiring less labor than other methods of cutting. In addition, it helps to eliminate errors that may occur during manual cutting.